Resistent to fresh & salt water

PC-11®

PC-11®

paste epoxy

SKU:010112

Couldn't load pickup availability

PC-11® thrives in wet environments. It is resistant to water whether it is fresh or salt. Thick consistency like PC-7® and long open time (30 min). Work horizontal or vertical, indoor or outdoor. Wet, dry or under water.

Whether you are working on an area where you just can’t remove water and moisture or you want the white color for your repair, PC-11® is your choice. Choose PC-11® for ceramic repairs, pools and spas, fiberglass boats, tubs and sinks, stock tanks and thousands of other repairs. It has excellent adhesive properties bonding metals, fiberglass, wood, tile and some plastics such as ABS and rigid PVC. Ample open time allows tooling or positioning in order to tackle larger and challenging jobs. When mixed, the epoxy, part A (white) and the hardener part B (lt. blue) react to form a bond of tremendous strength and flexibility. The PC-11® formulation is slow curing, but slow can be a good thing especially for large tasks.

WORKING TIME: 30 MINUTES

CURE TIME: 24 HOURS (48 HOURS FOR FULL CURE)

PC-11® is thick. Thick is good if you need to work vertically or want to hold an object in place. How thick? Not quite as thick as peanut butter.

Share

-

Properties

- Sets on wet or dry surfaces or underwater

- Extended working time to allow repositioning

- No drip or sag, even on overhead work

- Excellent chemical resistance to mild acids, caustics, detergents, gasoline, fuel oil, salt, and fresh water

- Waterproof

- Sandable and paintable

- Tintable

- Use as an adhesive, sealant and filler

-

Use on

Fibreglass, concrete, wood, metals, brick, glass, block, ceramics, rubber and more.

-

Example projects

- Reattach missing swimming pool tiles.

- Patch a hole in a fiberglass canoe or the fiberglass keel of a fishing boat.

- Repair cracked or damage swimming pool or hot tub skimmer.

- Waterproof and Seal cracked fiberglass.

- Seal screw holes to hatch lids or seating.

- Attach fish locators to transom.

- Repair stock tanks.

- Repair broken refrigerator door shelf fixtures.

- Repair broken pottery.

- Repair shower basin or antique bath tub.

- Seal leaking air conditioner drip pan.

- Seal underground conduit.

How to use PC-11®

Prep

Prepare your surface as best you can to ensure the best possible bond with PC-11®. Remove contaminants such as dust, dirt, oil, barnacles and grime with a solvent such as methylated spirit, acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner. Mild detergent solution in water is also good for removing contaminants. Do not use white spirit or paint thinner for removing contaminants. For a wet or underwater

surface; clean contaminants as best as you can. Solvents will not help you in this situation.

Remove rust and loose paint with sandpaper or wire brush. Epoxy typically sticks to most paints. If there’s a concern of the paint’s

adhesion then remove it with sandpaper or wire brush.

Smooth, glossy and shiny surfaces should be roughened using sandpaper to increase adhesion.

For outside repairs, be mindful of the temperature before starting. PC-11® will cure very slowly below 10°c and stop curing at or below freezing. If the temperature is above 35°c PC-11® will cure rapidly, reducing the working and application time.

Mixing

PC-11® has a work time of 30 minutes so only mix as much product as you think you can apply in this time. You will be able to apply more to continue filling across an area, PC-11® sticks to PC-11®.

PC-11® has a consistency that’s not quite as thick as peanut butter.

To mix PC-11® you’ll need a spatula, lolly stick or similar and probably a piece of scrap wood, cardboard or similar to mix on. We don’t recommend mixing in a cup or container as it can be hard to judge the % of parts. If the repair is outside and the weather is cool we’d recommend placing the tubs/syringe somewhere warm to reduce the viscosity.

PC-11® should be mixed with equal amounts of part A (white) and part B (light blue). If purchasing the 1oz syringe equal amounts will be dispensed from the nozzle and you simply need to mix them together.

If purchasing a larger size you will have two tubs. We generally recommend eyeballing the amounts but if more precise measurements are desired, based on an average net weight it is 107 grams part A to 100 grams part B.

The amounts should be as close to equal as possible, but a slight excess of part A is preferable

to an excess of part B. Excess of part B (the hardener) will not accelerate curing and may prevent it from hardening.

Eyeballing tip: Make a circular mound (like half a golf ball) of part A. Alongside but not touching, make a rounded mound of the same circumference, adding or taking away until the height matches the mound of part A.

When properly mixed the epoxy will all be one consistent colour.

Remember to use a different spatula/tool in each tub or wipe it off with methylated spirit on a cloth/kitchen roll in between! This will ensure that the rest of the tubs remain good and uncured for future use. Store in a cool location.

Tinting

PC-11 is tintable. However, PC-11 has a lot of TiO2 (white pigment) in it making it difficult to produce anything but pastels.

Underwater & Wet Use

Underwater repairs are difficult but it is possible to apply PC-11® underwater. We’d recommend practicing the following technique before attempting the repair:

- 1) Brush clean surface. Use methylated spirit or acetone to prep the surface, which will help PC-11® grab the wet surface.

- Measure and mix PC-11®.

- Apply it to a polythene sheet.

- Wait 20 – 30 minutes for it to stiffen a little.

- Press PC-11®/polythene patch into place.

- Wait 24 hours and remove polythene sheet.

There is the potential for PC-11® to harm sea life, but properly measured and mixed PC-11® has been used safely in fresh and salt water aquariums. It is important that parts A and B are thoroughly and

completely mixed.

Clean Up

After using PC-11® clean up using methylated spirit, acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner to clean tools and mixing surfaces before PC-11® cures.

Clean hands and skin with soap and water.

Cured epoxy can be removed by applying paint remover or paint stripper to soften the epoxy surface. Scratch off the softened epoxy. Repeat as needed.

Finishing

After PC-11® has fully cured it can be sawed, sanded, tapped, drilled, machined, filed and painted. We recommend allowing 24 hours to cure at 20°c (longer in cooler temperatures). It should reach full

hardness in 48 hours.

We recommend applying a stain-sealing primer/sealer to the repair before painting. A primer/sealer is essential if you are applying gel coat.

Downloads

Product Comparison Chart

Not sure which PC epoxy is right for your project? Take a look at our product chart for a quick comparison of some the key features of each our epoxies.

| HEAVY | CLEAR | PUTTY | WOOD | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PC-7® | PC-11® | PC-Auto Bond™ | PC-Super Epoxy® | PC-Clear™ | Tite-Chairs® | PC-Metal™ | PC-Marine™ | PC-Plumbing® | PC-Fahrenheit™ | PC-Woody® | PC-Petrifier® | PC-Rot Terminator™ | |

| Waterproof after cure | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | Limited | ✔ | |

| Apply to wet surface | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Tintable | ✔ | ✔ | ✔ | ✔ | |||||||||

| No drip or sag | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| NSF® rated | ✔ | ✔ | |||||||||||

| Fill characteristics | ★★★★ | ★★★ | ★★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★★ | ★ | |||

| Strength | ★★★ | ★★★ | ★★★ | ★★★★ | ★★★ | ★★★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★★ |

| Work time @ 21°c | 1 HR | 35 MIN | 8 MIN | 15 MIN | 4 MIN | 1-5 MIN | 3 MIN | 20 MIN | 3 MIN | 8 MIN | 30-40 MIN | 1-4 HR | |

| Service time @ 21°c | 12-24 HR | 8-15 HR | 1 HR | 3-4 HR | 1 HR | 15-30 MIN | 1 HR | 1HR | 1HR | 1HR | 12-24 HR | 24 HR | 3-7 DAY |

| Heat range | -30°c to 90°c | -30°c to 90°c | -30°c to 150°c | -30°c to 90°c | -30°c to 90°c | -55°c to 85°c | -30°c to 120°c | -30°c to 120°c | -30°c to 120°c | -30°c to 260°c | -30°c to 90°c | 0°c + | -30°c to 90°c |

| Tensile strength | 2150 PSI | 1710 PSI | 1700 PSI | 2650 PSI | 2300 PSI | 4000 PSI | 900 PSI | 700 PSI | 900 PSI | 700 PSI | 850 PSI | ||

| Colour | Dark grey | Off white | Metallic grey | Translucent | Clear | Clear | Dark grey | White | Grey | Brown | Tan | Milky white | Amber |

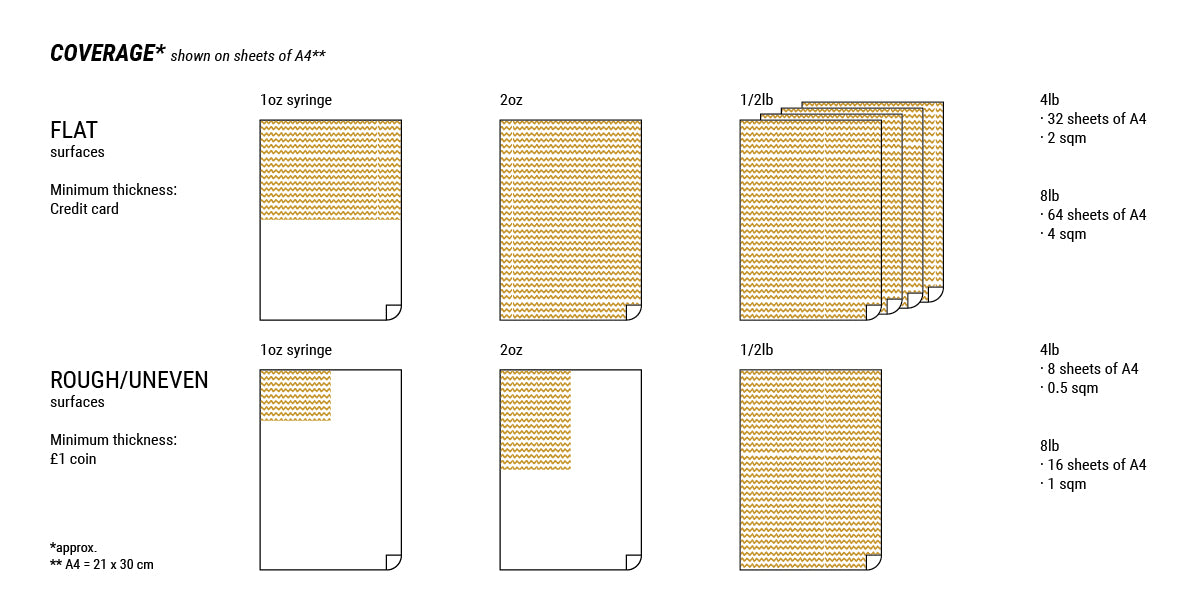

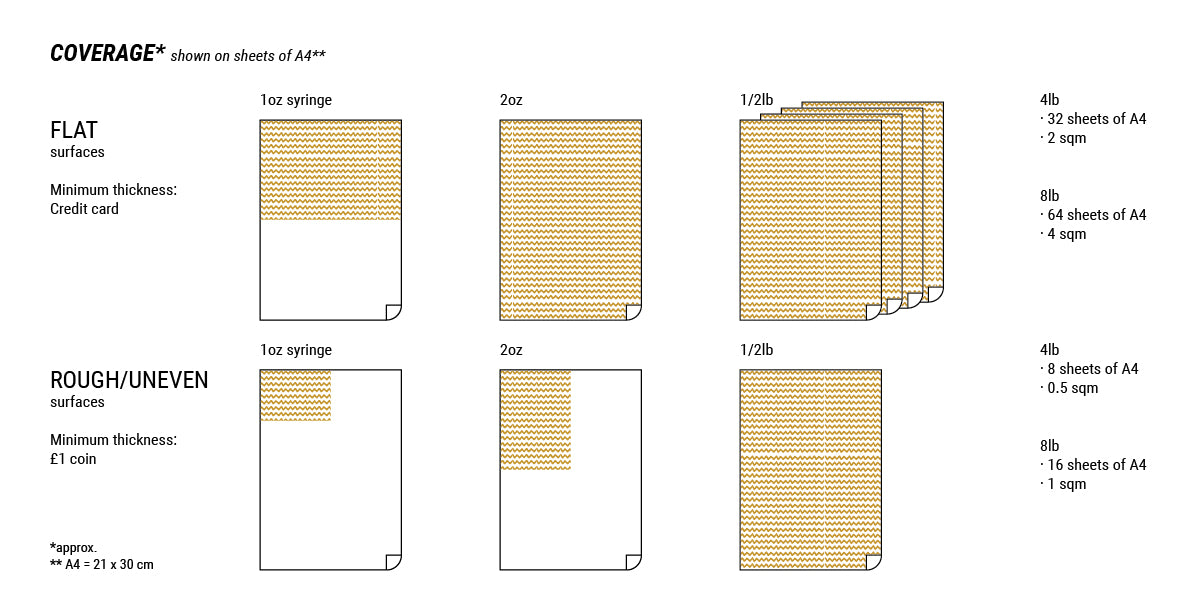

Imperial or Metric?

We got you...

1oz = 28g | 2oz = 57g | 6oz = 170g

1/2lb = 8oz = 227g | 1lb = 16oz = 454g

4lb = 64oz = 1.8kg | 8lb = 128oz = 3.6kg