A non-drip translucent paste epoxy

PC-SuperEpoxy®

PC-SuperEpoxy®

paste epoxy

SKU:016619

Couldn't load pickup availability

PC-SuperEpoxy® is a non-drip translucent paste epoxy suitable for conventional or static mixing. It has unlimited uses in bonding, assembling, filling and sealing most materials.

Unlike conventional liquid epoxies, PC-SuperEpoxy® can be applied via a static mix nozzle vertically and overhead. It cures quickly at room temperature to form a resilient, non-conductive bond or seal that resists most chemicals, fresh and salt water, gasoline and fuel oil. Works great bonding steel to wood, fiberglass, aluminum, concrete, brick, glass, block, ceramics, hard plastics and much more. PC-SuperEpoxy® is the toughest, highest strength epoxy we manufacture.

WORKING TIME: 15 MINUTES (TACK FREE IN 60 MINUTES)

CURE TIME: 4 HOURS (12-24 HOURS FOR FULL CURE)

Here is a product that can take on the most challenging of projects with ease.

Adhesion strength in excess of 2500 psi (up to 4000 psi).

PC-SuperEpoxy® is a gel with the consistency like Vaseline.

Share

-

Properties

- Quick-setting

- Sets on wet or dry surfaces or underwater

- Translucent

- No drip or sag, even on overhead work

- Excellent chemical resistance to mild acids, caustics, detergents, gasoline, fuel oil, salt, and fresh water

- Waterproof

- Sandable and paintable

- Tintable

- Use as an adhesive, sealant and filler

-

Use on

Fibreglass, concrete, wood, metals, brick, glass, block, ceramics, hard plastics and more.

-

Example projects

- Fix cracked wood beam

- Fix broken latch in car glove box

- Attach axe head

How to use PC-SuperEpoxy®

Prep

Prepare your surface as best you can to ensure the best possible bond with PC-SuperEpoxy®. Remove contaminants such as dust, dirt, oil and grime with a solvent such as methylated spirit, acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner. Mild detergent solution in water is also good for removing contaminants.

Use a clean paper towel or rag for wiping. Do not use white spirit or paint thinner for removing contaminants.

Remove rust and loose paint with sandpaper or wire brush. Epoxy typically sticks to most paints. If there’s a concern of the paint’s adhesion then remove it with sandpaper or wire brush.

Smooth, glossy and shiny surfaces should be roughened using sandpaper to increase adhesion.

Prepare your surface as best you can to ensure the best possible bond with PC-SuperEpoxy®. Remove contaminants such as dust, dirt, oil and grime with a solvent such as methylated spirit, acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner. Mild detergent solution in water is also good for removing contaminants. Use a clean paper towel or rag for wiping. Do not use white spirit or paint thinner for removing contaminants.

Remove rust and loose paint with sandpaper or wire brush. Epoxy typically sticks to most paints. If there’s a concern of the paint’s adhesion then remove it with sandpaper or wire brush.

Smooth, glossy and shiny surfaces should be roughened using sandpaper to increase adhesion.

Mixing

PC-SuperEpoxy® has a work time of 15 minutes so only mix as much product as you think you can apply in this time. You will be able to apply more to continue filling across an area, PC-SuperEpoxy® sticks to PC-SuperEpoxy®.

PC-SuperEpoxy® is a non-drip gel with a consistency similar to Vaseline.

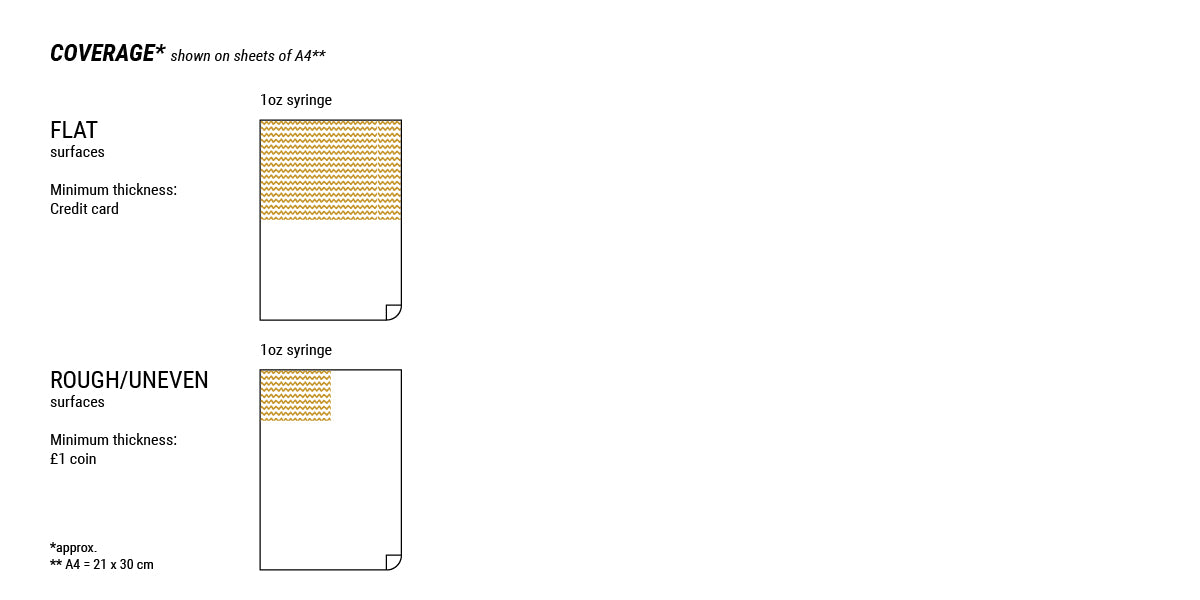

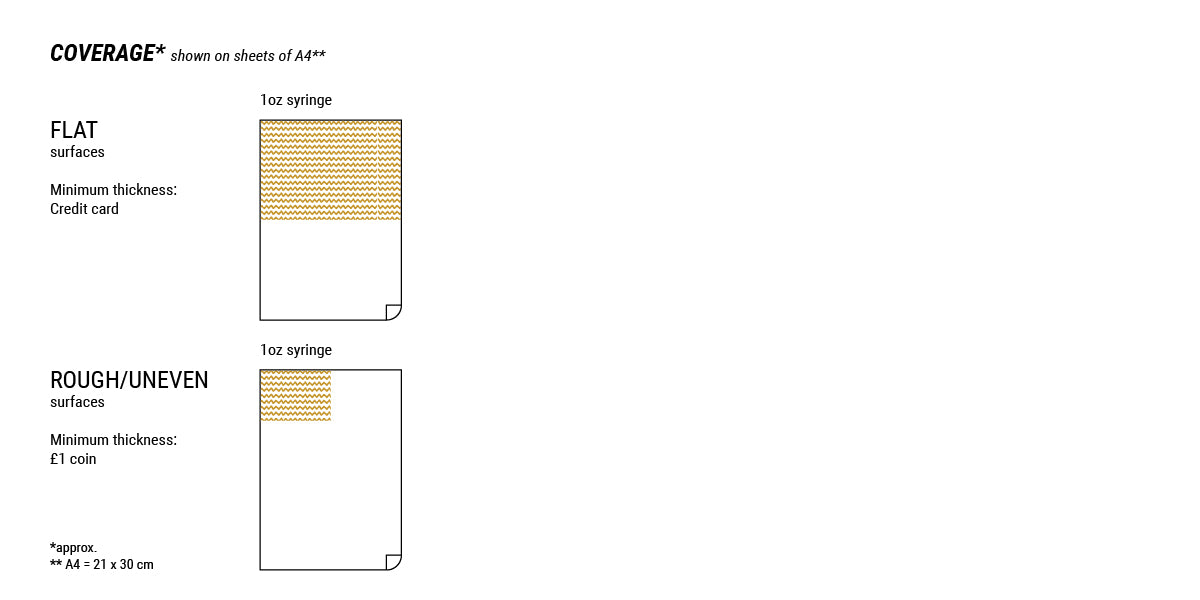

To mix PC-SuperEpoxy® you’ll need a spatula, putty knife or lolly stick and probably a piece of scrap wood, cardboard or similar to mix on. With the 1oz syringe equal amounts will be dispensed from the nozzle and you simply need to mix them together. A fading dye is used in part A to help you see when both parts have been mixed.

The syringe lid can be replaced after use to save the remainder for future repairs. Store in a cool location.

Tinting

Underwater & Wet Use

Clean Up

After using PC-SuperEpoxy® clean up using methylated spirit, acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner to clean tools and mixing surfaces before PC-SuperEpoxy® cures.

Clean hands and skin with soap and water.

Cured epoxy can be removed by applying paint remover or paint stripper to soften the epoxy surface. Scratch off the softened epoxy. Repeat as needed.

Finishing

PC-SuperEpoxy® will be tack free in 60 minutes.

After PC-SuperEpoxy® has fully cured it can be sanded and painted. We recommend allowing 4 hours to cure at 20°c (longer at cooler temperatures). It should reach full hardness in 12-24 hours.

We recommend applying a stain-sealing primer/sealer to the repair before painting.

Downloads

Product Comparison Chart

Not sure which PC epoxy is right for your project? Take a look at our product chart for a quick comparison of some the key features of each our epoxies.

| HEAVY | CLEAR | PUTTY | WOOD | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PC-7® | PC-11® | PC-Auto Bond™ | PC-Super Epoxy® | PC-Clear™ | Tite-Chairs® | PC-Metal™ | PC-Marine™ | PC-Plumbing® | PC-Fahrenheit™ | PC-Woody® | PC-Petrifier® | PC-Rot Terminator™ | |

| Waterproof after cure | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | Limited | ✔ | |

| Apply to wet surface | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Tintable | ✔ | ✔ | ✔ | ✔ | |||||||||

| No drip or sag | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| NSF® rated | ✔ | ✔ | |||||||||||

| Fill characteristics | ★★★★ | ★★★ | ★★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★★ | ★ | |||

| Strength | ★★★ | ★★★ | ★★★ | ★★★★ | ★★★ | ★★★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★★ |

| Work time @ 21°c | 1 HR | 35 MIN | 8 MIN | 15 MIN | 4 MIN | 1-5 MIN | 3 MIN | 20 MIN | 3 MIN | 8 MIN | 30-40 MIN | 1-4 HR | |

| Service time @ 21°c | 12-24 HR | 8-15 HR | 1 HR | 3-4 HR | 1 HR | 15-30 MIN | 1 HR | 1HR | 1HR | 1HR | 12-24 HR | 24 HR | 3-7 DAY |

| Heat range | -30°c to 90°c | -30°c to 90°c | -30°c to 150°c | -30°c to 90°c | -30°c to 90°c | -55°c to 85°c | -30°c to 120°c | -30°c to 120°c | -30°c to 120°c | -30°c to 260°c | -30°c to 90°c | 0°c + | -30°c to 90°c |

| Tensile strength | 2150 PSI | 1710 PSI | 1700 PSI | 2650 PSI | 2300 PSI | 4000 PSI | 900 PSI | 700 PSI | 900 PSI | 700 PSI | 850 PSI | ||

| Colour | Dark grey | Off white | Metallic grey | Translucent | Clear | Clear | Dark grey | White | Grey | Brown | Tan | Milky white | Amber |

Imperial or Metric?

We got you...

1oz = 28g | 2oz = 57g | 6oz = 170g

1/2lb = 8oz = 227g | 1lb = 16oz = 454g

4lb = 64oz = 1.8kg | 8lb = 128oz = 3.6kg