A two part epoxy paste made with real wood

PC-Woody®

PC-Woody®

paste epoxy

SKU:083338

Couldn't load pickup availability

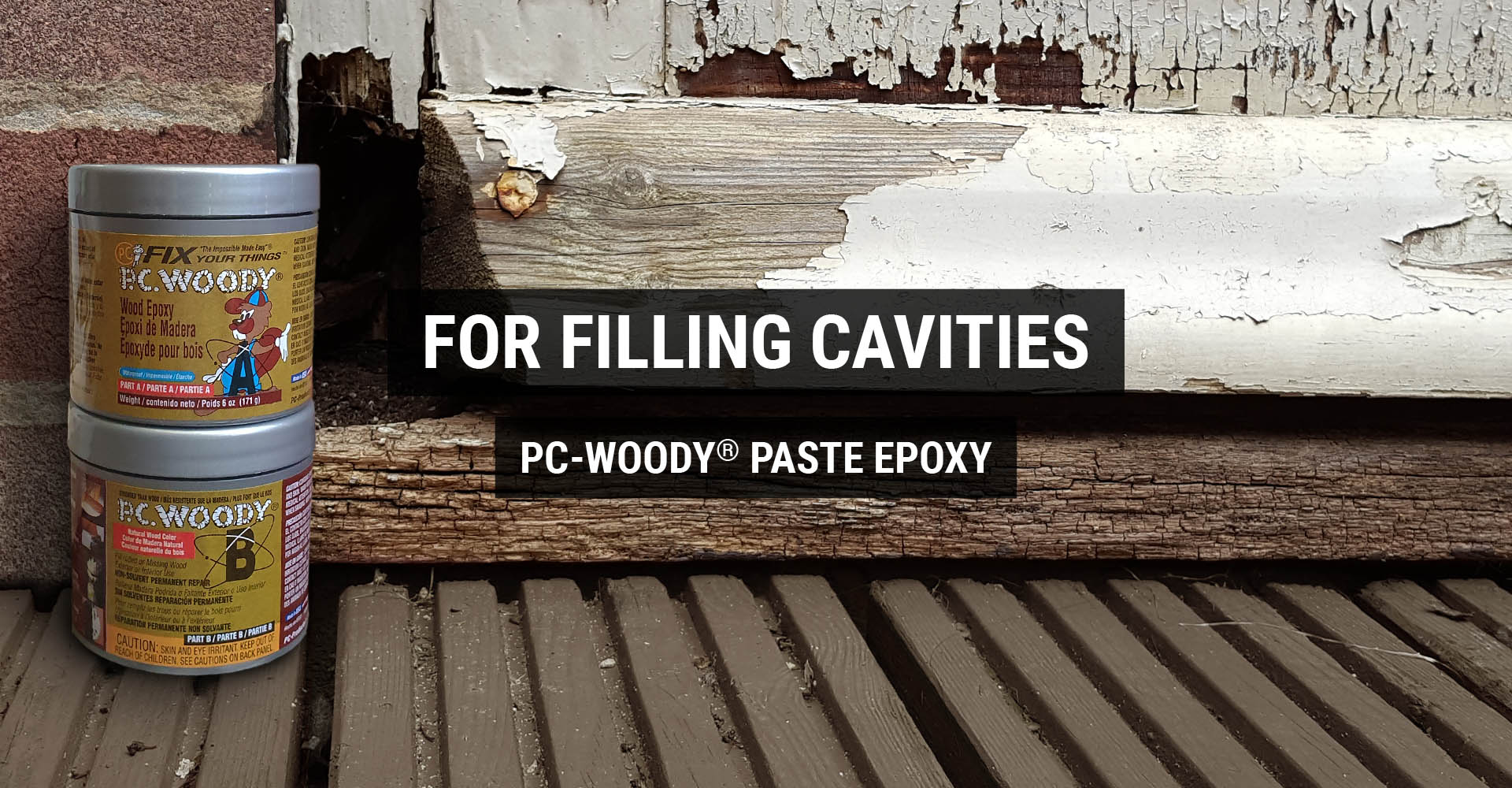

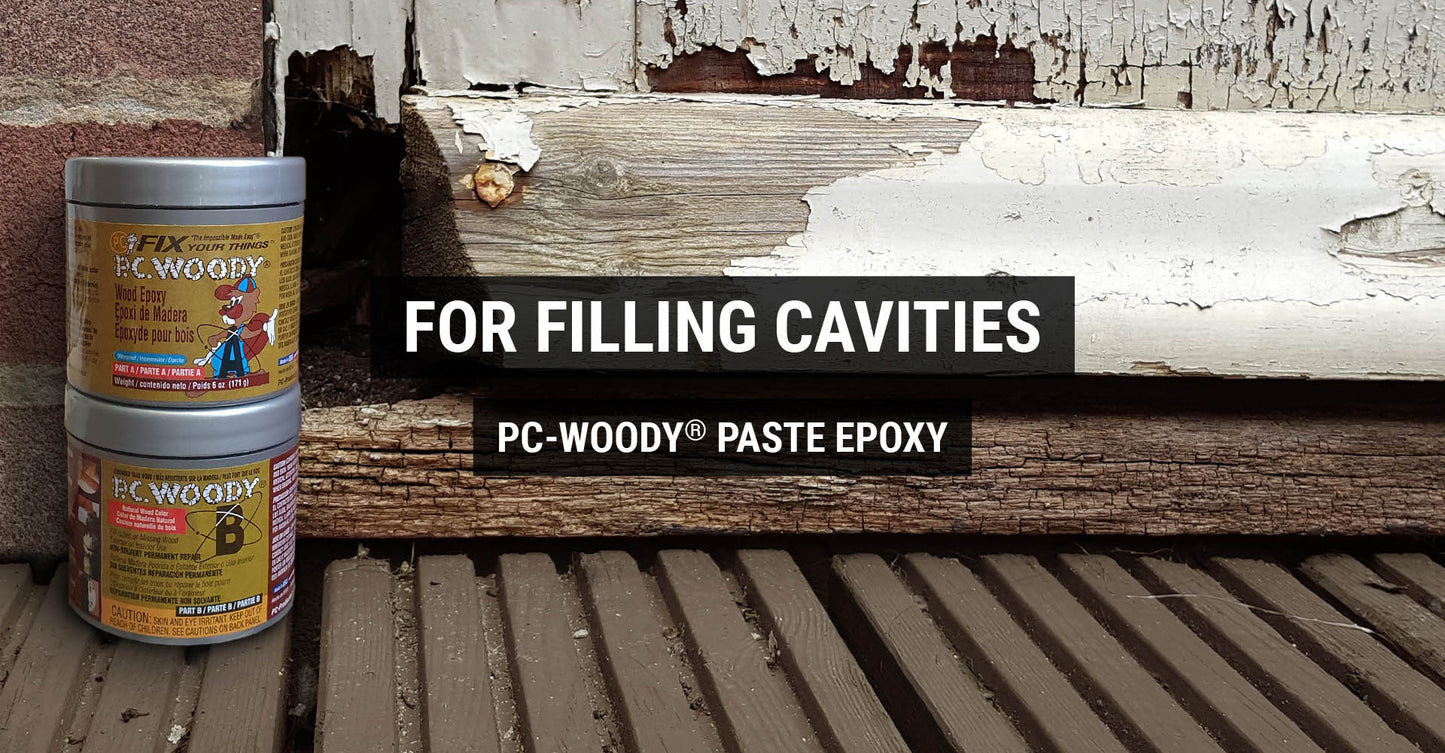

PC-Woody® is a two part epoxy paste that is excellent for filling cavities in wood.

Make permanent repairs without shrinking, cracking or popping out of exterior wood. Sand, drill, nail, prime and paint or stain. Bonding filler for replacement wood. Not brittle. Easy 1:1 mix ratio.

WORKING TIME: 90 MINUTES

CURE TIME: 24 HOURS

Share

-

Properties

- Permanent repair

- Interior or exterior applications

- Made from real wood

- Extended working time to allow repositioning

- No drip or sag, even on overhead work

- Excellent resistance to all weather elements, mildew dry rot, UV light, fresh and salt water and chemicals present in pressure-treated wood

- Waterproof

- Sandable and paintable

- Tintable and stainable

- Can be drilled, screwed and nailed

-

Use on

Log homes, furniture, window and door sills and more.

-

Example projects

- Fill gaps in previously rotten window sill

- Fill holes from wood knots in garden gates

How to use PC-Woody®

Prep

Prepare your surface as best you can to ensure the best possible bond with PC-Woody®. Remove loose paint, wood fibres and debris with a stiff brush, sandpaper or scraper. Remove contaminants such as dust, dirt, oil and grime with a solvent such as methylated spirit, acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner.

Wood that has been damaged by rot or infestations should be treated with a wood hardener such as PC-Petrifier® or PC-Rot Terminator®.

For outside repairs, be mindful of the temperature. In temperatures below 10°c the curing time will increase and you may wish to use a heat source such as a heat lamp to accelerate the curing. Heat guns and hair dryers should be used with caution because they can be too intense. We do not recommend applying PC-Woody® at temperatures at or below freezing (curing will pause, resuming as temperatures improve).

Mixing

PC-Woody® has a work time of 30-40 minutes so only mix as much product as you think you can apply in this time. You will be able to apply more to continue filling across an area, PC-Woody® sticks to PC-Woody®.

To mix PC-Woody® you’ll need a spatula, putty knife or similar (something stiff) and probably a piece of scrap wood, cardboard or similar to mix on. We don’t recommend mixing in a cup or container as it can be hard to judge the % of parts and will accelerate the reaction. PC-Woody® that is spread out will have a longer worktime than in a container. If the repair is outside and the weather is cool we’d recommend placing the tubs somewhere warm to reduce the viscosity.

PC-Woody® should be mixed in equal parts, one part A (white) to one part B (brown). Off-ratio measurement is the main cause of soft cured PC-Woody®. The amounts should be as close to equal as possible, but a slight excess of part A is preferable to an excess of part B. Excess of part B (the hardener) will not accelerate curing and may prevent it from hardening. We generally recommend eyeballing the amounts but if more precise measurements are desired, based on an average net weight it is 10.6 parts A to 10 parts B.

Eyeballing tip: Make a circular mound (like half a golf ball) of part A. Alongside but not touching, make a rounded mound of the same circumference, adding or taking away until the height matches the mound of part A.

When properly mixed the epoxy will all be one consistent colour.

Remember to use a different spatula/tool in each tub or wipe it off with methylated spirit on a cloth/kitchen roll in between! This will ensure that the rest of the tubs remain good and uncured for future use. Store in a cool location.

Tinting

PC-Woody® contains real wood and can be tinted and stained, tinting being the most effective of the two.

Tinting: Tinting with colourant or dry pigments is effective. It can be difficult to match colours with pigments or universal colour dispersions. Darker tinting is less obvious than lighter. You could use the sediment of a settled stain to tint PC-Woody® but dry pigments would be preferable.

Staining: PC-Woody® can be stained after sanding. The results will vary depending on the stain. Lighter colour stains are ineffective. Using semi-transparent stain is possible but results will vary depending on the stain. Stains that contain only dye will produce disappointing results. Use stains containing greater pigment.

Stain markers and pencils can add grain.

Underwater & Wet Use

Clean Up

After using PC-Woody® clean up using methylated spirit, acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner to clean tools and mixing surfaces before PC-Woody® cures.

Clean hands and skin with soap and water.

Cured epoxy can be removed by applying paint remover or paint stripper to soften the epoxy surface. Scratch off the softened epoxy. Repeat as needed.

Finishing

After PC-Woody® has fully cured it can be sanded, carved and can take screws and nails. We recommend allowing 12 hours to cure at 20°c (longer at cooler temperatures). It should reach full hardness in 24 hours. See the Prep section for more information on curing in cool temperatures.

Sanding: 80 grit sandpaper works well on PC-Woody®. Fine sandpaper such as 120, 150 and 180 can also be used. Mechanical sanders work best after 48 hours. Wear a respirator and ventilate mechanically.

Turning: PC-Woody® can be turned on a lathe but it will do so differently than wood. Wear a respirator and ventilate mechanically.

Fixings: It is best to drill a pilot hole before using screws and nails.

We recommend applying a stain-sealing primer/sealer to the repair before painting. A primer/sealer is essential if you are applying gel coat.

Downloads

Product Comparison Chart

Not sure which PC epoxy is right for your project? Take a look at our product chart for a quick comparison of some the key features of each our epoxies.

| HEAVY | CLEAR | PUTTY | WOOD | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PC-7® | PC-11® | PC-Auto Bond™ | PC-Super Epoxy® | PC-Clear™ | Tite-Chairs® | PC-Metal™ | PC-Marine™ | PC-Plumbing® | PC-Fahrenheit™ | PC-Woody® | PC-Petrifier® | PC-Rot Terminator™ | |

| Waterproof after cure | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | Limited | ✔ | |

| Apply to wet surface | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Tintable | ✔ | ✔ | ✔ | ✔ | |||||||||

| No drip or sag | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| NSF® rated | ✔ | ✔ | |||||||||||

| Fill characteristics | ★★★★ | ★★★ | ★★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★★ | ★ | |||

| Strength | ★★★ | ★★★ | ★★★ | ★★★★ | ★★★ | ★★★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★ | ★★★ |

| Work time @ 21°c | 1 HR | 35 MIN | 8 MIN | 15 MIN | 4 MIN | 1-5 MIN | 3 MIN | 20 MIN | 3 MIN | 8 MIN | 30-40 MIN | 1-4 HR | |

| Service time @ 21°c | 12-24 HR | 8-15 HR | 1 HR | 3-4 HR | 1 HR | 15-30 MIN | 1 HR | 1HR | 1HR | 1HR | 12-24 HR | 24 HR | 3-7 DAY |

| Heat range | -30°c to 90°c | -30°c to 90°c | -30°c to 150°c | -30°c to 90°c | -30°c to 90°c | -55°c to 85°c | -30°c to 120°c | -30°c to 120°c | -30°c to 120°c | -30°c to 260°c | -30°c to 90°c | 0°c + | -30°c to 90°c |

| Tensile strength | 2150 PSI | 1710 PSI | 1700 PSI | 2650 PSI | 2300 PSI | 4000 PSI | 900 PSI | 700 PSI | 900 PSI | 700 PSI | 850 PSI | ||

| Colour | Dark grey | Off white | Metallic grey | Translucent | Clear | Clear | Dark grey | White | Grey | Brown | Tan | Milky white | Amber |

Imperial or Metric?

We got you...

1oz = 28g | 2oz = 57g | 6oz = 170g

1/2lb = 8oz = 227g | 1lb = 16oz = 454g

4lb = 64oz = 1.8kg | 8lb = 128oz = 3.6kg